抽油泵是有杆采油系统中的主要设备,通过抽油机、抽油杆传递的动力进行油井内液体的抽汲。

是油田有杆采油作业中最常见、应用范围最广的一种地面动力设备。

- API Spec 11AX

- GB/T18607-2001

- API会标使用许可证

产品符合API Spec 11AX《抽油泵及其组件规范》、GB/T18607-2001《抽油泵及其组件规范》及其它相关标准,取得API会标使用许可证。

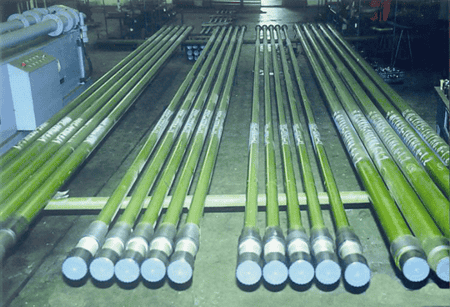

公司可生产符合标准规范的管式泵、杆式泵及防气泵、防砂泵、防盐泵等特种抽油泵。

需要订购吗?现在就联系我们吧!

技术性能特点

1、泵筒采用优质专用管材、内表面采用镀铬或镍磷复合镀等表面强化处理,强度高、刚性好、耐磨、耐腐蚀。

2、柱塞表面采用镍基合金粉末喷焊处理,耐磨、耐腐蚀。

3、阀球和阀座采用高碳铬不锈钢或陶瓷、碳化钨等材料制成,使用寿命长。

4、泵效高,检泵周期长。

5、结构简单、使用安装方便。

生产机房

详细参数

| Type | Model | Pump bore in(mm) |

Plunger Length ft(m) |

Barrel Length ft(m) |

Tubing OD in(mm) |

Sucker Rod Diameter in(mm) |

Extension Length ft(m) |

Well Condition |

|---|---|---|---|---|---|---|---|---|

| Tubing Pump | 20/25-106TH | 11/8 (26.99) | 2(0.6)~7(2.1) | 11(3.3)~31(9.5) | 23/8(60.3)~27/8(73.0) | 5/8(15.9)~3/4(19.1) | 2(0.6)~3(0.9) | The well contains salt, sulfur, C02, bacilli, corrosive medium and little sand |

| 20/25-125TH | 11/4 (31.8) | 2(0.6)~7(2.1) | 11(3.3)~31(9.5) | 23/8(60.3)~27/8(73.0) | 5/8(15.9)~3/4(19.1) | 2(0.6)~3(0.9) | ||

| 20/25-150TH | 11/2 (38.1) | 2(0.6)~7(2.1)) | 11(3.3)~31(9.5) | 23/8(60.3)~27/8(73.0) | 3/4(19.1) | 2(0.6)~3(0.9) | ||

| 20/25-175TH | 13/4 (44.5) | 2(0.6)~7(2.1)) | 11(3.3)~31(9.5) | 23/8(60.3)~27/8(73.0) | 3/4(19.1) | 2(0.6)~3(0.9) | ||

| 25-200TH | 2 (50.8) | 2(0.6)~7(2.1)) | 11(3.3)~31(9.5) | 27/8(73.0) | 3/4(19.1) | 2(0.6)~3(0.9) | ||

| 25-225TH | 21/4 (57.2) | 2(0.6)~7(2.1)) | 11(3.3)~31(9.5) | 27/8(73.0) | 3/4(19.1) | 2(0.6)~3(0.9) | ||

| 30-275TH | 23/4 (69.9) | 2(0.6)~7(2.1)) | 11(3.3)~31(9.5) | 31/2(88.9) | 7/8(22.2) | 2(0.6)~3(0.9) | ||

| 40-375TH | 33/4 (95.3) | 2(0.6)~7(2.1)) | 11(3.3)~31(9.5) | 41/2(114.3) | 1(25.4) | 2(0.6)~3(0.9) | ||

| Rod Pump | 20-125RH/W | 11/4 (31.8) | 2(0.6)~7(2.1)) | 11(3.3)~31(9.5) | 23/8(60.3) | 3/4(19.1) | 2(0.6)~3(0.9) | |

| 25-150RH/W | 11/2 (38.1) | 2(0.6)~7(2.1)) | 11(3.3)~31(9.5) | 27/8(73.0) | 3/4(19.1) | 2(0.6)~3(0.9) | ||

| 25-175RH/W | 13/4 (44.5) | 2(0.6)~7(2.1)) | 11(3.3)~31(9.5) | 27/8(73.0) | 3/4(19.1) | 2(0.6)~3(0.9) | ||

| 25-200RH/W | 2 (50.8) | 2(0.6)~7(2.1) | 11(3.3)~31(9.5) | 27/8(73.0) | 3/4(19.1) | 2(0.6)~3(0.9) | ||

| 30-225RH/W | 2 1/4 (57.2) | 2(0.6)~7(2.1) | 11(3.3)~31(9.5) | 31/2(88.9) | 3/4(19.1) | 2(0.6)~3(0.9) | ||

| Sand control pump with long plunger | 25-125~225TH | 11/4 (31.8)~21/4 (57.2) | 11(3.3)~21(6.3) | 4(1.2)~7(2.1) | 27/8(73.0) | 3/4(19.1) | / | High sand well |

| Bridge linkage pump | 25-150~225TH | 11/2 (38.1)~21/4 (57.2) | 2(0.6)~7(2.1) | 11(3.3)~31(9.5) | 27/8(73.0) | 3/4(19.1) | / | High sand well |

| Slim hole pump | 25-125~175TH | 11/4 (31.8)~13/4 (44.5) | 2(0.6)~7(2.1) | 11(3.3)~31(9.5) | 27/8(73.0) | 3/4(19.1) | / | Casing repair well or Slim hole well |

| Anti-salt pump with long plunger | 25-125~225TH | 11/4 (31.8)~21/4 (57.2) | 11(3.3)~31(9.5) | 4(1.2)~7(2.1) | 27/8(73.0) | 3/4(19.1) | / | Severe orystallizing salt well |

| Gas control pump | 25-125~225TH | 11/4 (31.8)~21/4 (57.2) | 4(1.2)~7(2.1) | 11(3.3)~31(9.5) | 27/8(73.0) | 3/4(19.1) | / | High gas well |

| Heavy crude pump using liquid rotary | 25-150/225TH | 11/2 (38.1)/21/4 (57.2) | 2(0.6)~7(2.1)) | 11(3.3)~22(6.6) | 27/8(73.0) | 3/4(19.1) | / | Heavy crude well |

| 25-175/225TH | 13/4 (44.5)/21/4 (57.2) | 2(0.6)~7(2.1) | 11(3.3)~22(6.6) | 27/8(73.0) | 3/4(19.1) | / | ||

| Slant hole pump | 25-150~225TH | 13/4 (38.1)~21/4 (57.2) | 2(0.6)~7(2.1) | 11(3.3)~31(9.5) | 27/8(73.0) | 3/4(19.1) | / | Limited leaning degree |

| 27/8(73.0) | 3/4(19.1) | / |